Ceramic Treatments That Last

Boost Durability and Performance with Innovative Blasting Solutions

Do you want to increase the life of your part by 20%?

Are you looking for help to improve performance, increase efficiencies or solve a problem?

Are you looking for a non-ferrous, non-magnetic blasting abrasive?

Premium Ceramic Abrasives by Saint-Gobain – Exclusively Distributed by Vixen Surface Treatments

Saint-Gobain is one of the world’s leading manufacturers of ceramic abrasives. Here at Vixen Surface Treatments, we are the sole distributor of Saint Gobain Zirpro products.

Our range of ceramic abrasives cleans many industrial parts such as moulds and dies, engine parts, turbine machinery components, welded steel components, forged and casted metals, automotive parts and much more.

Success in Every Detail

TEST EXPERIENCE CENTRE

73 Jay Avenue, Teesside Industrial Estate, Thornaby, Stockton on Tees, TS17 9LZ, UK

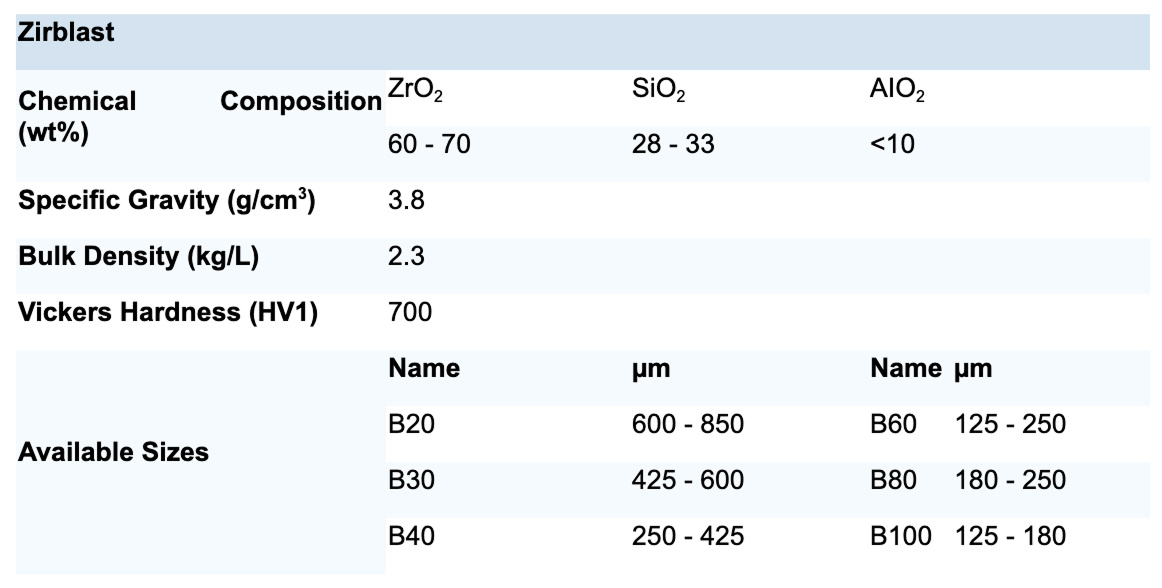

Zirblast®

Saint-Gobain is one of the world’s leading manufacturers of ceramic abrasives. Here at Vixen Surface Treatments, we are the sole distributor of Saint Gobain Zirpro products.

Zirblast® ceramic beads are used as blasting media for blast cleaning and surface preparation applications. Zirblast beads are durable blasting media that offer effective cleaning power with no surface contamination to deliver a smooth satin finish. They are suitable for blasting the surface of all kinds of steel, aluminium, and other non-ferrous alloys to remove oxide, rust, sand, coatings and burrs. Ceramic beads are easy to handle in all categories of dry or wet blasting machinery, including pneumatic blasting rooms. They also are well suited for working in most kinds of wheel turbine blasting machines.

Peening with Zirshot ceramic shots offers:

- High level of compressive stress near the surface

- Smooth surface finish that minimizes crack initiation

- Very low material abrasion that maintains accuracy of fine geometries

- High rebound that allows homogeneous coverage of intricate geometries

- Very low levels of particle embedment

- No need for decontamination post-treatments for non-ferrous alloys

- Cost savings on the downstream processes (coating, polishing)

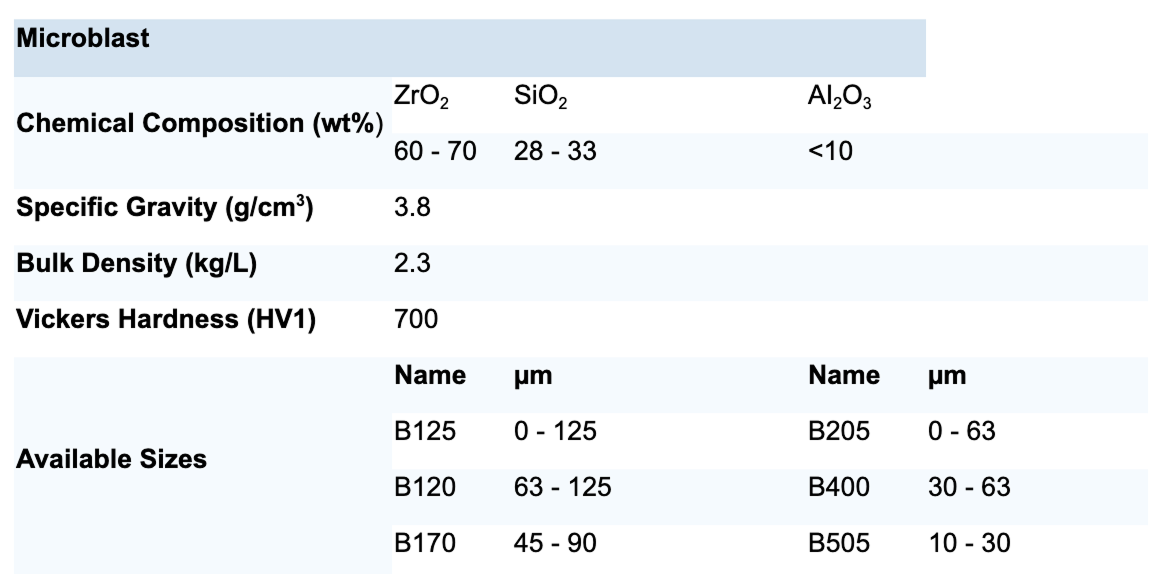

Microblast®

Microblast fine ceramic beads are used as blasting media for surface finishing applications. Microblast B205, B170 and B120 blasting beads deliver the smoothest finish and a unique satin effect on stainless steel, aluminium, titanium, magnesium and even plastic surfaces. The Microblast product line is the industry standard in blasting media, delivering high-quality components with superior aesthetics in a variety of applications including automotive, aerospace, electronics, home appliances, sporting goods and architecture. With their unique characteristics, Microblast ceramic beads also are used for precision blast cleaning applications to achieve the smoothest and most uniform surface finish on treated parts.

Download PDF technical sheet To deliver the highest and most consistent standards of quality, Microblast fine ceramic beads undergo a fully controlled process as well as a stringent product quality inspection through advanced technologies such as particle size laser diffraction and morphological imagery. This enables our customers to achieve blasted components with perfect and stable surface finishes.

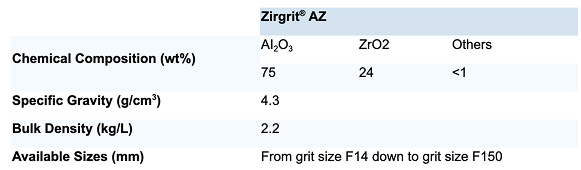

Zirgrit®

Zirgrit® AZ is an Alumina – Zirconia composite grain, manufactured with the Saint-Gobain unique fusion process. Their superior chemistry and microstructure provide higher efficiency and durability, in comparison to traditional blasting materials like fused alumina. Zirgrit®

AZ can be used in all blast cleaning applications as a cost-effective solution to traditional blasting grits, thanks to a much longer durability (x3 to x6 in a dry application and much longer in a wet application), a higher consistency in the surface finish with less particle embedment, and a lower quantity of waste material to handle.

The chemical composition of Zirgrit® AZ has been defined in order to achieve improved performance in comparison to fused alumina:

- Longer durability (x3 to x6)

- More consistency in Surface Finish

- Less particle embedment on the blasted substrate

- No ferrous contamination

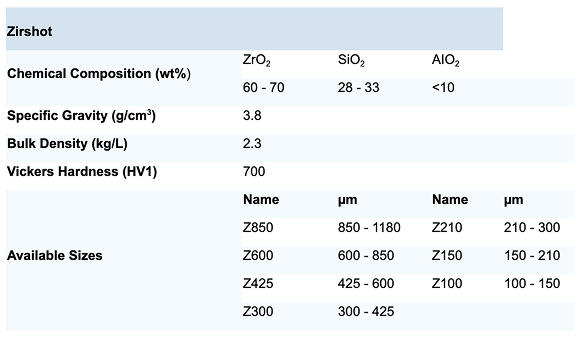

Zirshot®

Saint-Gobain Zirshot® is the industrial reference media for ceramic shot peening, enhancing the fatigue resistance of mechanical parts made of metallic alloys such as hard steel, titanium and aluminium. In shot forming, Zirshot also is used to shape and straighten slim hard alloys for aerospace structural components.

Zirshot combines the high hardness (700HV) and toughness of ceramic materials with optimal spherical bead shape and tight size distribution, resulting in outstanding peening benefits:

- High energy transfer at the impact point on the metallic substrate

- Preservation of the integrity of the peened surface with a mooth and uniform surface finish

Because the quality of peening media is a critical parameter that directly impacts the service life of treated components, ZirPro manufactures shot peening media using tightly controlled procedures and specifications, enabling Zirshot to conform to the most stringent aerospace and automotive ceramic shot peening standards.